- Leading Provider

- OF INDUSTRIAL SOLUTIONS

- Certified Company

- ISO 9001:2015

- ACMA - Award

- UDAY PRIDE TIER II CLUSTER

Manufacturing Technology

HOT FORGING

Rohan Industries enjoys a great advantage in hot forging as it houses conventional and highly flexible forging lines that help the company to meet different client’s demands at the same time. With the optimum utilization of the capacity, the company stays in the position to exercise efficiency and economy in its operations which translates into cost benefit for the clients.

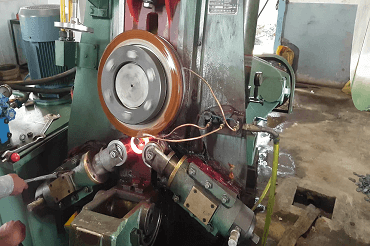

Vertical Forging Lines

Vertical Forging Lines play a vital role in forging for bearing rings and automotive components. These lines are suitable for low and medium volume of production batch quantity.

- Rohan’s vertical forging lines facility is equipped with.

- 3 Vertical Hot Forging Line with Friction Screw Press, Capacity 0.1kg to 1.5kg

- 1 Profiled Hot Forging Ring Rolling Machine, Capacity Dia 50mm to 200mm

- 125 and 250kw Induction Heaters with Hot Shearing Press Machine

Annealing & Normalizing

Rohan Industries possesses state of the art furnaces for carrying out various kind of Annealing and Normalizing Processes viz. Spheroidized annealing, ISO thermal Annealing, Solution annealing, Stress reliving etc. All the furnaces are certified as per Standards and automatically controlled.

- Rohan’s annealing and normalizing facility is equipped with.

- 2 Bell Type Furnace having capacity of 2 tons each

MACHINING PROCESS

Right from forging to finish machining process, the entire value added chain is the key to Rohan’s cost effective of components based on forged parts. Striving to sustain perfect precision engineering in all the segments of production, Rohan Industries persistently works on new developments in machining process. Rohan’s machining facility, carrying out variety of operations like turning, drilling, milling etc., is technologically upbeat to take its manufacturing standards to level of excellence. It is fortified with CNC and VMC machines.

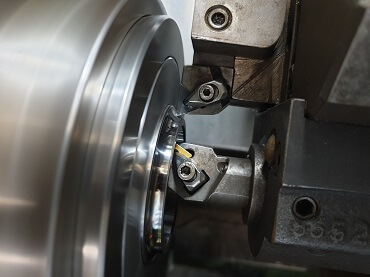

CNC Machines

Right from forging to finish machining process, the entire value added chain is the key to Rohan’s cost effective of components based on forged parts. Striving to sustain perfect precision engineering in all the segments of production, Rohan Industries persistently works on new developments in machining process. Rohan’s machining facility, carrying out variety of operations like turning, drilling, milling etc., is technologically upbeat to take its manufacturing standards to level of excellence. It is fortified with CNC and VMC machines.

Over a period of time, Rohan Industries has replaced its conventional Lathe machines with Auto Loaded CNC Machines with centralized cheap and coolant systems, delivering greater productivity and sustainability in the quality. In addition to it, special fixtures are developed for the automated CNC lines to avoid three points – two points lobbing.

- Rohan’s CNC Line is equipped with :

- 8 spindles under Single Roof with world class Technology along with Hard Turning Lines for auto components.

- CNC turning machine for large size ring up to 250 mm diameter.

- CNC machine for shaft turning.

CNC Hard Turning Process

We better understand the hard-turning process, there are significant benefits including eliminating investment in specialized grinding equipment, and the ability to perform multiple CNC machining operations with one setup, thus improving throughput and reducing cost-per-part. We are Maintaining Higher Dimensional Accuracy and Surface Roughness Finish (RA) in our regular production.

VMC Machines

- VMC for Precision Machining operation. The machines possess and output capacity of up to 300 mm OD

- Machining for Precision Automotive Components and Precision Industrial Parts.